What are the types of markings, why are they needed, and how to choose the right bearings for rollers.

Bearings are the heart of roller skates. In this case, it does not matter at all what type of rollers we are talking about.

It is the bearing that makes the wheels rotate, thanks to which the latter allow the rollers to develop the desired speed. The quality of the bearings directly affects the results of the skaters in competitions and marathons, and also affects the comfort in amateur skating.

This large and concise guide will not only help you understand the differences but also easily identify the type of part that is right for your style and level of riding.

Standards (brands) of bearings

All bearings are divided into 2 standards (brands): 608 and 688. They are also called size.

- Grade 608 is based on the standardization of the production process: the number 60 indicates the product series, and the number 8 indicates the inner diameter of the bearing.

Classic inline skates and quad skates are usually equipped with 608 standard bearings, which are easy to maintain and allow you to keep high speed when skating for a long time.

- The 688 grade has the same 8mm OD and 8mm ID as the 608 standard bearings, but they are thinner, reducing their weight by 2.5 times.

Standard 688 bearings also accelerate well and hold speed, but are more sensitive to dirt, dust, water, and therefore require more careful maintenance.

ABEC bearing markings

In the production of roller skates (as well as skateboards and scooters), bearings are usually marked with the designation “ABEC” with the addition of an odd number from 1 to 9.

The abbreviation ABEC itself stands for quite unusually as the Annular Bearing Engineering Council or “Bearing Development Committee”, and the figure characterizes the accuracy of tolerance during production. At the same time, the smaller the number, the lower the tolerance (not speed!), And, accordingly, the cost of the part.

What is the difference between markings (classes)?

Estimating the speed of rotation of a bearing by class is the biggest misconception of buyers. Many people think: the higher the number in the marking, the faster the videos will go. But it’s not.

The marking determines how accurately the bearing is made. And the larger the number, the more “jewelry” and more ideally the detail is made.

The class will affect roller roll (rolling duration without additional push) and durability, but not speed. In addition, the marking determines which style of riding the part is suitable for.

What does speed depend on?

We have already found out that the number in the marking is not an indicator of speed. So ABEC 9 bearings by default may not be the fastest, but will provide longer torque.

And the following factors can affect the speed:

- The quality and consistency of the lubricant used

A more plastic and thicker lubricant slows down the rotation speed, but at the same time increases the service life.

Conversely, liquid lubrication allows for better acceleration at first, but quickly evaporates, flows out and requires very frequent maintenance for bearings. In addition, the use of the latter is completely inappropriate for videos from the “fitness” series.

- Quality and frequency of service

Bearings of any marking (provided there is no marriage) for the first time after purchase will properly perform their function. But depending on the “mileage” and riding conditions, the performance will gradually worsen.

The load and duration of riding will require a renewal of the lubricant over time, and the inevitable ingress of dust, sand and dirt will require timely cleaning and possibly even replacement of the part.

Differences between ABEC markings

As we mentioned above, according to the marking, you can select spare parts depending on the style of riding. In addition, it is worth explaining the purpose of other models of bearings from the popular manufacturer Powerslide, which causes the most questions.

The most popular markings: ABEC 1, ABEC 3, ABEC 5, ABEC 7, ABEC 9:

- ABEC 1 and ABEC 3 have a lower accuracy class but higher impact resistance. Often installed in scooters, skateboards, and roller skates of a very low price segment;

- ABEC 5 is the most widely used inline skates for children, fitness, FSK, slalom, and aggressive skating from many manufacturers, due to the optimal ratio of price and quality;

- ABEC 7, ABEC 9 – less resistant to impact, but better at long-term loads. From here they find applications mainly in fitness videos and models for speed skating.

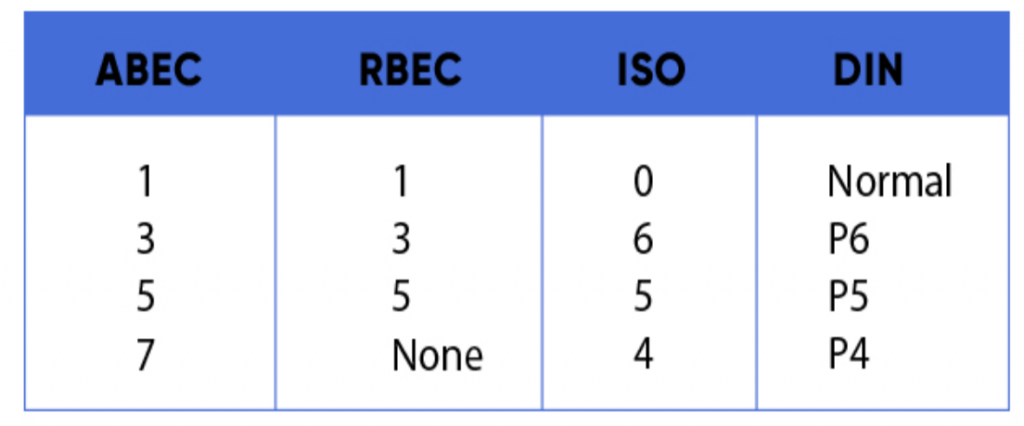

In addition to the ABEC marking, there are other accuracy classes:

- RBEC – Roller Bearing Manufacturers Association

- ISO – International Organization for Standardization

- DIN – German Industrial Standards.

The correspondence of these classes and ABEC is presented in the table below:

Other types of bearings from Wicked

Powerslide’s sister brand, Wicked, also produces bearings for inline skates such as Rustproof, Twincam ILQ9, Swiss, and others.

- Twincam ILQ7, ILQ9 Pro / Classic (Inline Line Quality)

Unlike ABEC, which is an approved industry standard, ILQ is not a bearing quality standard but simply refers to the name used in Twincam bearings for marketing purposes.

Twin cams have similar markings to ABEC and are of good quality. The “Pro” bearings have a nylon cage and are typically used by speedskaters, while the “Classic” has a steel cage, which is more suitable for city and freestyle riding;

- Rustproof SUS – suitable for riding (mostly training, but not competition) in wet conditions. Made of stainless steel and less susceptible to corrosion;

- Swiss is a Swiss-made model that does not have any ABEC marking but is distinguished by the highest technical characteristics, quality, and speed. That is why many athletes in high-speed roller skating give preference to her.

Based on the manufacturer’s own comments, of all the “unbranded” models listed, Swiss bearings are by far the fastest, followed by ILQ Pro, ILQ Classic, and completing the Rustproof SUS rating.

Used technologies and materials

- Freespin technology involves the use of a special lubricant that provides a smooth surface and fast rotation of Wicked ABEC 5, ABEC 7, and ABEC 9 bearings. This bearing consists of an inner and outer ring, balls, and a raceway

- Ceramic – ceramic bearings that offer the benefits of reduced friction, weight, and increased wear resistance

Most ceramic bearings are hybrid bearings, where ceramic balls are combined with a steel outer and inner ring and raceway. Fully ceramic options are quite rare due to their high cost.

Professional ceramic bearings are made of silicon nitride (Si2N4), usually black in color, about 30% stronger than steel bearings, more rounded and smoother with a versatile shape that guarantees a significant reduction in friction.

Related Post: How to choose wheels for roller skates? Detailed guide

- Stainless steel is a material that combines chromium (not less than 10.5%), carbon (not more than 1.2%) with the addition of nickel or other elements. Such material is permanently covered with a protective layer of chromium oxide, which is formed on the surface naturally, due to the reaction of chromium and water from the air. If the surface is scratched, the protective layer is regenerated again, which protects the stainless steel from corrosion.

These bearings are mainly used for wet weather riding (for example, for off-road skates or in high-speed races and marathons).

- Chrome steel is an alloy of iron, carbon, and some other elements, which is obtained by immersing ordinary steel in a solution with electrolytes containing chromium and allowing a protective layer to form.

The most popular material for the inner ring, outer ring, balls, and raceways in the bearing is 52100 series chrome steel. With special heat treatment and smooth surface, each component provides high resistance to bearing fatigue, as well as fast and quiet rolling.

- Carbon steel is a high-tech material that is used in aviation, Formula 1 cars, and a huge range of sports equipment but often misleads consumers when it comes to bearings.

Carbon steel bearings do not withstand high loads at high speeds and are not resistant to corrosion. Strong friction between the balls and the raceway significantly reduces speed and productivity. Such products have a low cost and, as a rule, are used in budget models of videos for beginners.

- Carbon hybrid steel is used in the Wicked Carbon Pro bearings, a combination of chrome and carbon steel.

The outer and inner rings, along with the raceway, are made of stronger chrome steel, and the balls are made of carbon steel. These bearings provide a more comfortable and smooth ride than models made entirely of carbon steel.

Seals in bearings

The seal is required for:

- uniform distribution of balls and lubricant around the raceway

- prevent them from rubbing against each other

- achieve high speed.

To improve accuracy and prevent additional abrasion, it is important that the seal does not allow excessive radial movement. To do this, the seal is guided either by balls or by one of the rings.

Types of seals in bearings:

- steel (from different types of steel that we discussed above) – widely used in production, usually have the shape of a crown and are guided by an inner ring.

They have disadvantages in the form of a large weight, the risk of deformation of the protective coating upon impact, corrosion of carbon steel.

- plastic – composite products, most often made of reinforced nylon by injection molding. Polyacetal (POM) can also be used.

Polymeric materials such as polyethylene (PE) are used with stainless steel bearings, while polyester ether ketone (PEEK) is most commonly used with ceramic bearings.

The plastic crown covers the ball guide. Unlike steel, the plastic seal has a higher sliding performance and causes sharp temperature fluctuations in the operating torque. This allows you to increase the maximum speed by 60% with low noise.

The disadvantages listed for steel retainers, on the contrary, are advantages for plastic ones.

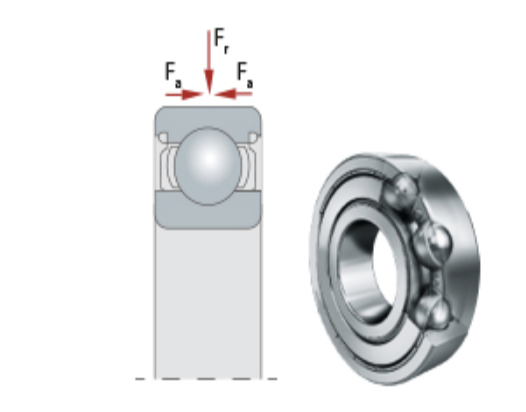

- ZZ (2Z)

Bearings with such a seal are coated on both sides with a non-removable seal that does not come into contact with metal and is fixed on the outer ring by pressing. The seal is not removable after factory assembly. This means you won’t be able to disassemble the bearings, only doing basic maintenance like cleaning the outer race and wiping down moisture after riding in wet weather.

The abbreviation Z in the suffix indicates the presence of one shield, and ZZ (or Z2) – two.

Used in commercials of the low price segment.

- ZZS / ZS is a removable seal that does not come into contact with metal and is attached with a snap-on wire ring (C-ring). This technology does not allow contact with the inner ring.

Advantages of the C-ring fastening: does not create excessive friction and heat, does not allow leakage of lubricant (in the ZZS version), does not require frequent maintenance.

Disadvantages: poor protection against dust and water ingress (especially in the ZZ version).

- 2RU / RU – seal, which is made of nitrile rubber (NBR) connected to a steel sleeve. Mounted on the outer ring through a special recess (groove). It can be removed, but be very careful not to bend or cut the edges.

The seal has a very thin lip that does not come into contact with the inner ring, which provides higher protection than in ZZ and ZZS. It is important to use the correct cleaning materials as various types of lubricants and chemicals often react with rubber.

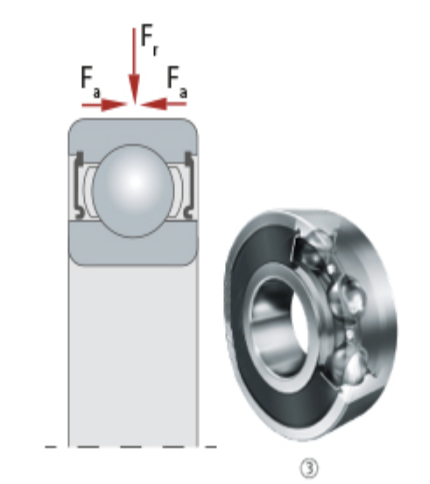

- 2RS / RS – Removable molded protective seal also made of rubber (NBR), attached to the outer ring through a groove.

In such bearings, a rubber seal is in contact with the inner ring, which, unlike a metal screen, increases protection against dirt and water from entering the part. On the other hand, it increases friction and reduces the ability to develop high speed.

- Labyrinth seal (screen) – also made of rubber (NBR) and completely fills the space between the inner and outer ring of the bearing.

The seal is connected to the inner ring by means of grooves, which improves tightness and prevents the penetration and accumulation of dirt and moisture inside, and also reduces the frequency of part maintenance without affecting the torque.

This type of seal is most commonly used in stainless steel bearings that are suitable for wet weather riding.

Bearings of closed and semi-closed type

Based on the name, you can guess that closed bearings are equipped with a seal on both sides, and semi-closed bearings are equipped with only one.

It is important that in a semi-closed bearing, the open side faces the inside of the wheel to keep dirt and moisture out.

Advantages of semi-closed bearings: lighter in weight and maintenance. Disadvantages: not protected from dirt and water, fast evaporation of grease, more frequent maintenance.

Bearing lubricants

The lubricant forms a thin film between the contact points of the bearing elements (balls and raceway) to prevent friction, heat, and corrosion.

Lubricant affects the maximum speed, heating temperature, torque level, noise, and durability of the part.

Types of greases for bearings:

- Mineral or synthetic lubricant – most often used in bearings designed for high-speed riding.

There are many types of synthetic oils available on the market. And every professional speedskater has a secret trick up his sleeve that makes his bearings faster. And some rollers do not use any lubricants at all.

Mineral and synthetic lubricants differ in viscosity. And the lower it is, the more liquid the material will be: it will be easier to apply it to the bearing, the friction force will decrease, the speed will increase, but the rapid evaporation will require more frequent maintenance.

- Silicone grease – has a wide temperature range, changes viscosity to a lesser extent when heated, repels water well.

Not used for high-speed riding, but best suited for wet weather riding.

- Grease is a mixture of oils with a thickener that allows the material to stay inside the bearing for longer, thus reducing the need for frequent maintenance.

Excessive amounts of such grease in the bearing reduce its performance and leads to increased resistance. Free space in the bearing is necessary to release heat between the balls and the raceway.

- Teflon is an additive used in grease that inhibits corrosion and improves the performance of standard grease.

Bearing maintenance

The first sign that bearings need to be diagnosed is a sound or slow rotation. Regular maintenance of the parts will at least save money.

For this you need:

- Disassemble the wheel and remove the bearing

- Remove the seal (if possible) with a needle

- Place all parts in a small container with a non-aggressive cleaning agent

- Gently clean each component with a brush

- Dry clean parts on a towel

- Lubricate the bearing with synthetic or any other grease

- Assemble the bearing and insert it into the wheel.

There is no general advice on how often bearings should be serviced, and there is no ideal range for washing a car.

Each roller is different. The main thing is not to forget to wipe and dry the wheels after each ride in wet weather, and at the slightest discomfort or suspicion that something is wrong with the bearings, pay close attention to this yourself or with the help of a specialist.